15P 100Ohms PTC Thermistor For Inverter Welding Machine

Product Details:

| Place of Origin: | UL,SGS,ROHS |

| Brand Name: | UCHI |

| Certification: | UL,SGS,ROHS |

| Model Number: | PTC15P100Ohms |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5000PCS |

|---|---|

| Price: | Negotiable |

| Delivery Time: | 7 working days |

| Payment Terms: | T/T,Paypal,Western Union,Money gram |

| Supply Ability: | 600,000,000PCS Per Month |

|

Detail Information |

|||

| Highlight: | 100Ohms PTC Thermistor,15P PTC Thermistor |

||

|---|---|---|---|

Product Description

PTC 15P 100Ohms for welding machine/PTC thermistor/Inverter welding machine special

Quick Details

1. Silicon temperature sensors have a TK (temperature coefficinet) which is nearly constant over the complete temperature range. Temperature coefficient:α25/50≥0.7%/C.

2. Excellent long term stability, annual diversification rate≤0.01C/per year, temperature drifts during the lifetime of silicon temperature sensor are negligible.

3. Thermal Time Constant: 10 seconds max in still air.

4. Operating temperature range:-10~+45℃.

5. Dissipation factor:2.5--5mW/C.

6. Maximum operating current:Iopr=1.0mA.

7. Rated power:10mW.

8. Typical resistance @25C 600 ohm, 1000 ohm, 1600 ohm, 2000 ohm.

Description

Linear PTC Thermistor (LPTC) resistance increases with the temperature rises in linearity, displays a virtually linear positive temperature coefficient over their entire temperature range, suitable in measurement and control system, temperature compensation. As the construction material is mainly semiconductor monocrystalline silicon, also called silicon temperature sensor, silicon thermistor, sometimes referred to as silistors. As the temperature coefficient is positive, the silicon temperature sensors exhibit fail-safe operation when a system overheats. Furthermore silicon is inherently stable, so silicon temperature sensor are extremely reliable and have very long operational lifetimes. Hermetically sealed glass package, axial leaded, 2 leads, can operate in high temperature and moisture environment. Linear PTC thermistor in small dimension, tightness, convenient for automatic installation.

Application

· Industrial auotomation control equipment.

· Home appliance temperature detection and compensation.

· Precision circuit and crystal oscillator temperature compensation.

· Temperature compensation of silicon semiconducting devices.

· Temperature compensation of instrumentation amplifier.

· A/D converter temperature compensation. · Micro motor timing control.

· Automobile temperature detection and control.

· Medical equipment temperature detection and control.

· Linear PTC thermistor applications also include transmission, engine oil and coolant, heating system, overheating protection, amplifiers, power supplies, transducers, telemetry, computers, magnetic amplifiers, thermometry, meteorology, temperature regulation and over-temperature protection.

Specification

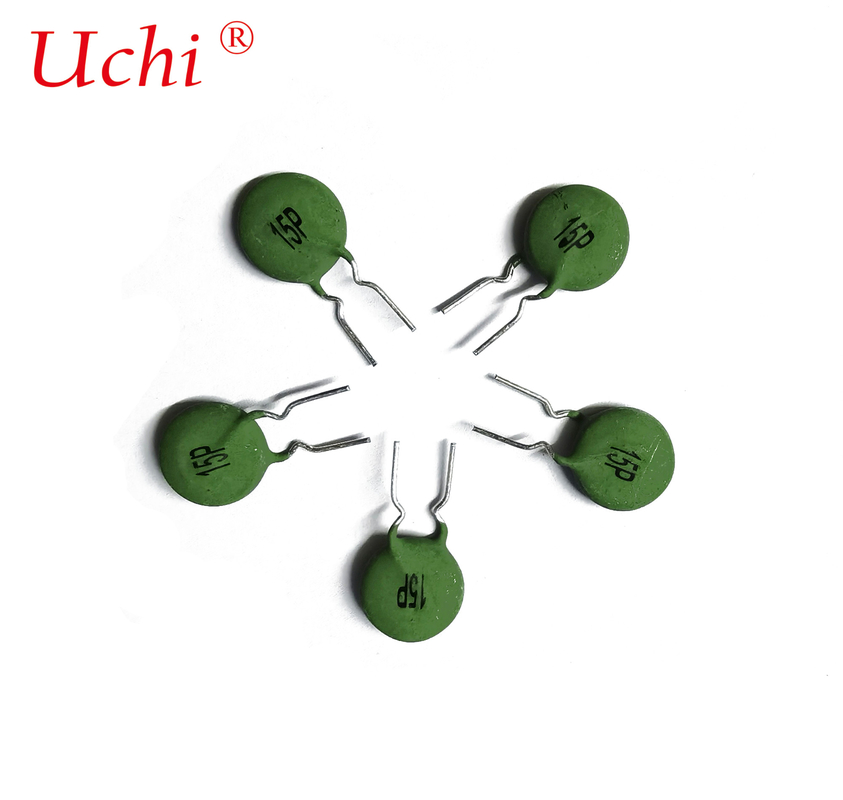

1. Part Name:PTC Thermistor 15P 100Ω

2,Specifications of Appearance

![]()

2-1,Dimensions (mm)

| Code | Name | Technicalrequirements |

| D | Diameter max | 15.0 |

| T | Thickness max | 6.5 |

| L | Lead length | 7±0.05 |

| W | Lead spacing | 7.5±1.0 |

| d | Lead diameter | 0.8±0.05 |

| Type | In-Forming |

2-2,Material and Marking:

| Material | Colour | Leads | Marking | Marking Colour |

| Silicon | Green | Tin-plated steel wire | 15P | Black |

3.Performance Specification

| Item | Specification | Test Conditions & Methods |

| 3-1Rated Zero-Power Resistance | 100Ω±30% | Ambient temp. Range:25℃±2℃(TA). Testing voltage: ≤1.5VDC Accuracy of instrument: ±0.5% |

| 3-2non-operating current | 100mA ΔR/Ro≤50% ΔR=∣Ro-Ro'∣ | Ambient temp. Range:25℃±2℃(TA). Testing voltage: 220Vac After placing for 1hours under TA, the resistance value shall be measured. |

| 3-3Operating Current | 600mA ΔR/Ro≥50% ΔR=∣Ro-Ro'∣ | Ambient temp. Range:25℃±2℃(TA). Testing voltage: 220Vac Line current:600mA PTC should enter high resistance (R>5*Ro) within 5min. |

| 3-4Withstand voltage test | 600Vac ΔR/Rn≤20% No visible mechanical damage

| Starting current: 4A; Start at 220Vac for 5S, then switch to high voltage 600Vac for 15S. After 4-5 hours of recovery under normal temperature and humidity conditions, retest the rated zero power resistance value. |

| 3-5Operating time | t≤15S | The PTC was placed at an ambient temperature of 25℃±2℃. The power supply voltage is 220V, the starting current is 4.0A, and the time t when the PTC current drops to 2.0A is detected. |

3-5The Curie temperature

| 120℃±10℃ | The resistance measured at Tc is equal to 2*Ro. |

| 3-6Insulation test | ≥100 MΩ | Testing voltage: 500V |

3-7 Environment test | According to the national standard of electronic components |

4.Mechanical characteristics

| Item | Specification | Test condition / Method | |

| 4-1 | Solder-ability | The terminals shall be Uniformly tinned,and its area≥95%

| Dipping the NTC terminals to a depth of 15mm in a soldering bath of 255 ± 10℃ and to the place of 6mm far from NTC body for 3±0.5s (See IEC68-2-20 /GB2423.28 Ta )

|

| 4-2 | Resistance To Soldering Heat | Resistance change rate before and after test. ΔR/Ro ≤20%(ΔR =∣Ro-Ro'∣) | Conduct the test according to IEC68-2-20 (GB2423. 28) test Tb..After recovering4-5h under 25±2℃. The rated zero power resistance value RN' shall be measured. (See IEC68-2-20 /GB2423.28 Tb)

|

| 4-3 | Strength of lead terminal | No break out

| Fasten the body and apply a force gradually to each lead until 10N and then keep for 10sec, Hold body and apply a force to each lead until 90°slowly at 5N in the direction of lead axis and then keep for 10sec, and do this in the opposite direction repeat for other terminal. After recovering 4~5h under 25±2℃, the rated zero power resistance value RN' shall be measured. (See IEC68-2-21/GB2423.29 Ua / Ub) |